Flexible film suitable for overmoulding and in-mould decoration. Tuneable size.

Flexible film suitable for overmoulding and in-mould decoration. Tuneable size.

Flexible film suitable for overmoulding and in-mould decoration. Tuneable size.

Flexible film suitable for overmoulding and in-mould decoration. Tuneable size.

Flexible film suitable for overmoulding and in-mould decoration. Tuneable size.

Flexible film suitable for overmoulding and in-mould decoration. Tuneable size.

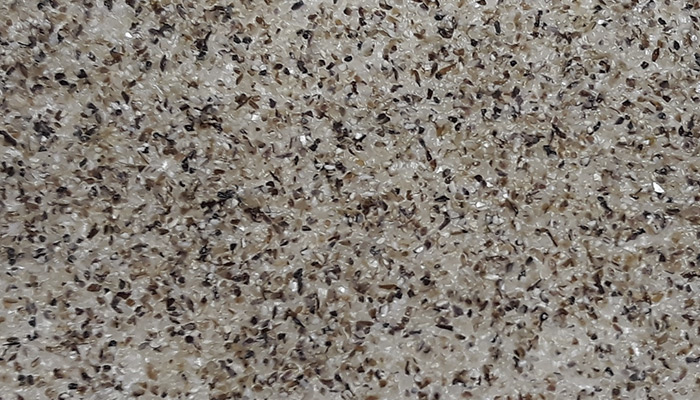

Seashell powder + plastic pellets.

Seashell powder + plastic pellets.

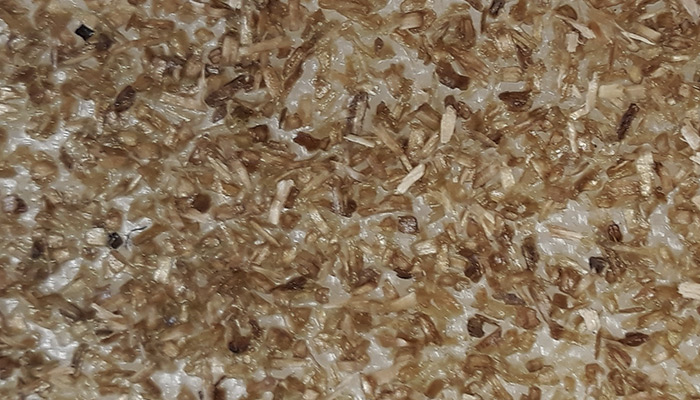

Pinecone particles + plastic pellets.

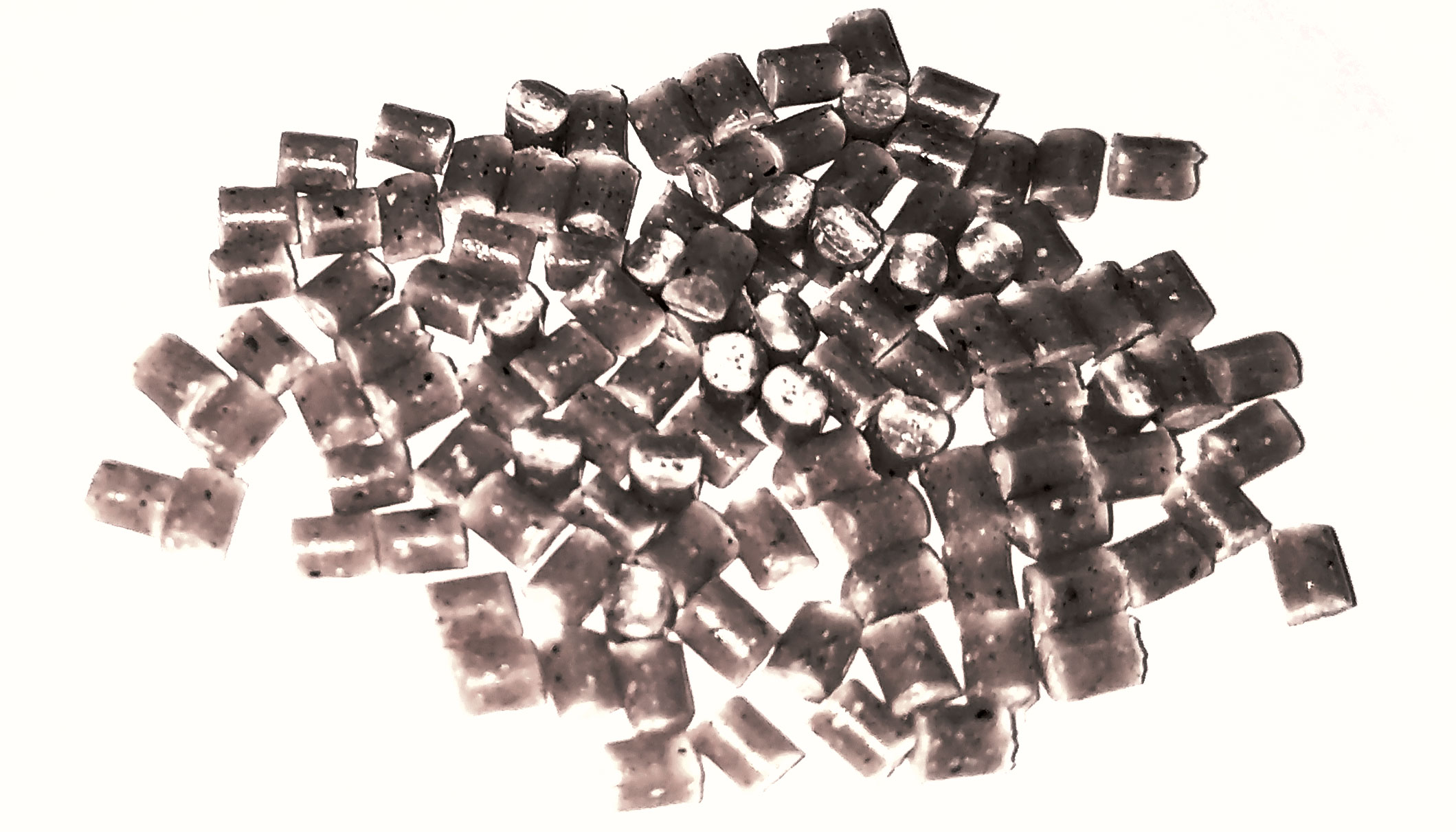

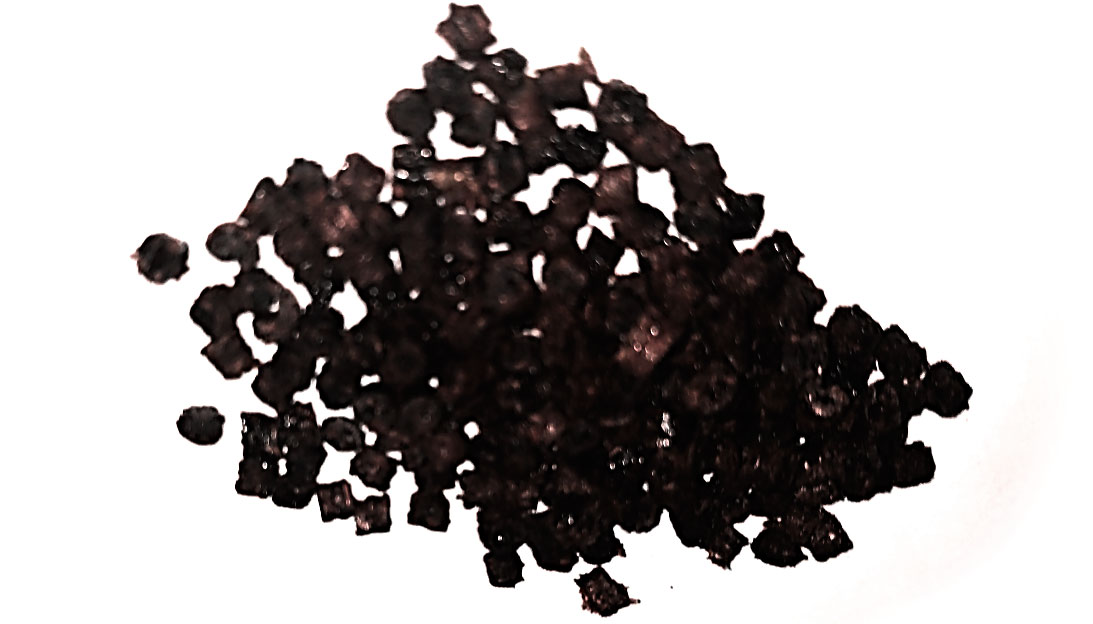

Polypropylene + 30 % of ADOLFO DOMINGUEZ wood fibers

Polypropylene + 30 % of KIWI fibers

.

Polypropylene + 30 % of NITENS fiber

Polypropylene + 40 % of NITENS fiber

Polypropylene + 30 % of STONE powder

Polypropylene + 30 % of GORSE fiber

Polypropylene + 30 % of GRAPEVINE fiber

Polypropylene + 30 % of broom fiber